WIB-52PC Automatic Injection Blow Molding Machine

General Description

The structure of the WIB-52PC automatic injection blow molding machine for sports bottle provided by Liuzhou Jingye Machine Co.,Ltd. is double-station, which include preform injection and blow molding ejection. It takes the one-step method forming process that means the injection, blow molding process and other processes are finished one by one in this machine. This kind of product shows that it is highly automatic with beautiful appearance of the product, accurate size and labour saving. This series injection blow molding machine for sports bottle provides higher productivity and quality.

Model: WIB-52PC

Blow Molding Type: Injection blow molding

Applicable Materials:PC, PMMA, PETG, PES, PPSU, TRITAN

Maximum Capacity: 2000ML

Note:We can provide customized injection blow molding machine for sports bottle and mould according to client requirement to meet the special need of your product.

Applications

With high quality and accuracy, our machines are mainly used to produce sports bottle, baby feeding bottle, LED lampshade and so on,and these products are used by AVON, STARBUCKS COFFEE and sold in WALMART etc.

Pictures of the Ready-made

Series of Whirlwind WIB Injection-Blow Molding

Blow Molding Injection Preform

product Preform up

Advantages

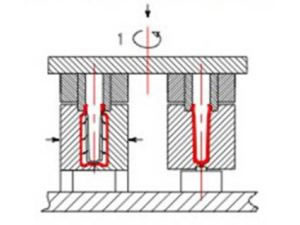

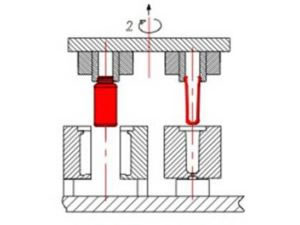

1. The injection and blow molding form in one step and don’t need secondary operation by worker. The products produced by the injection blow molding machine for sports bottle have the superiority in beautiful appearance, accurate size, good sealing property and compliance with GMP requirement.

2. Due to its character of full-automatic, this kind of automatic blow molding machine is of high degree of automation that is controlled by computer with the performance of steady work of hydraulic pressure and high production capacity.

3. Higher efficiency, lower energy consumption, better configuration.

4. The injection blow molding machine for sports bottle adopts the vertical work way to reduce projection area of the mold and use lower clamping force to finish the work, so as to achieve the effect of reducing energy consumption.

5. The mould of the automatic blow molding machine adopts the insert structure of overall preform mould that ensure the final products only have two parting lines.

6. Rich technology experience and strong ability to develop new product. We can provide customized injection blow molding machine for sports bottle and mould according to client’s requirement to meet the special need of your product.

WIB-52PC Main Specifications

| NO | Item | Unit | Data | NO | Item | Unit | Data | NO | Item | Unit | Data |

| 1 | Screw Diameter | mm | 52 | 6 | Blow Clamping Force | KN | 65 | 10 | Compressed Air | Mpa | 0.8~1.2 |

| 2 | Screw Speed | r/min | 0~180 | 7 | Production Speed | pcs/h | 300~720 | 11 | Cooling Water | bar | 1~3 |

| 3 | Theoretical Injection Capacity | g | 320 | 8 | Motor Power | KW | 22 | 12 | Dimension of Machine | cm | 340×140×240 |

| 4 | Injection Clamping Force | KN | 350 | 9 | Heater Capacity | KW | 13 | 13 | Machine Weight | Kg | 5000 |

| 5 | Suitable Materials | PC、PMMA、PETG PES、PPSU 、TRITAN | |||||||||

Product-related Configuration/ Parts

| No. | Item | Brand |

| 1 | All Hydraulic Valve | YUKEN |

| 2 | Variable Pump | YUKEN |

| 3 | Seal Ring | HALLITE |

| 4 | Hydraulic oil motor | INTERMOT |

| 5 | Cylinder Air Valve | SMC |

| 6 | Air Cylinder | SMC/AIRTAC |

| 7 | PLC | OMRON |

| 8 | Rotation Plant Servo Motor | OMRON |

| 9 | Low-voltage electrical components | Schneider |

| 10 | Temperature controller | OMRON |

| 11 | Material used for mould | Mould Stainless Steel |

WIB-52PC Injection Blow Molding Machine

WIB-52PC Injection Blow Molding Machine Sports Cup Making Machine

Sports Cup Making Machine Sports Bottle Blow Molding Machine

Sports Bottle Blow Molding Machine Baby Feeding Bottle Making Machine

Baby Feeding Bottle Making Machine Cosmetic Jar Making Machine

Cosmetic Jar Making Machine Cosmetic Jar Blow Molding Machine

Cosmetic Jar Blow Molding Machine