PE Bottle Blow Molding Machine

Description

PE bottle blow molding machine is suitable for producing PE plastic containers and bottles in all shapes. It is widely used to produce the pesticide bottle, oil bottle, cosmetics, and medicine bottle etc. Injection blow molding machine is suitable for producing high quality plastic bottles that is used as medicine and cosmetic.

Blow molding type: Injection blow molding

Applicable Materials:PE and other thermoplasticity resin raw materials

Maximum capacity: 2-800ML containers

Note:The bottle forming line of our company in China can provide customized machine and mould according to client requirement to meet the special need of your product.

Pictures of the Ready-made

Series of Whirlwind WIB Injection-Blow Molding

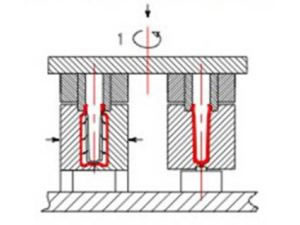

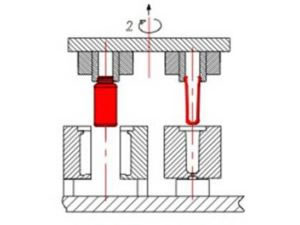

Blow Molding Injection Preform

product Preform up

Advantages

1. PE bottle blow molding machine is an advanced machine for mass production.

2. From feeding preform to finish blowing are fully automatic process, mass production and labor cost be tremendously saved in the bottle forming line of our company in China.

3. This machine is also equipped with touch screen for the operator to adjust each function easily.

4. This kind of PE bottle blow molding machine takes PLC control system for high speed information communication and high precision temperature control.

5. Hot-runner injection blow mold with horizontal three positions for continuous production with no leftovers or waste material.

6. Top brand electric parts and hydraulic parts for long service life.

7. A great variety of resins are applicable for a comprehensive production, which including: PE, PP, PS, and SAN.

8. The PE bottle blow molding machine provides fast molding performance without scrap or parting lines on the bottom or side.

9. Maximum uniformity of bottle weight, thickness and capacity.

10. Bottle body, neck and mouth can be varied to meet specific requirements.

11. Continuous production with no leftovers or waste material.

12. The PE bottle blow molding machine adopts precise time control system to assure good quality, suitable weight and reduce production cycle.

Main Specifications for PE Bottle Blow Molding Machine

| NO | Item | Unit | Data | NO | Item | Unit | Data | NO | Item | Unit | Data |

| 1 | Screw Diameter | mm | 40 | 6 | Blow Clamping Force | KN | 32 | 10 | Compressed Air | Mpa | 0.6~1.2 |

| 2 | Screw Speed | r/min | 0~180 | 7 | Production Speed | pcs/h | 1100~2000 | 11 | Cooling Water | bar | 1~3 |

| 3 | Theoretical Injection Capacity | g | 150 | 8 | Motor Power | KW | 15 | 12 | Dimension of Machine | cm | 290×140×220 |

| 4 | Injection Clamping Force | KN | 200 | 9 | Heater Capacity | KW | 7 | 13 | Machine Weight | Kg | 4500 |

| 5 | Suitable Materials | PE | |||||||||

Product-related Configuration/ Parts

| No. | Item | Brand |

| 1 | All Hydraulic Valve | YUKEN |

| 2 | Variable Pump | YUKEN |

| 3 | Seal Ring | HALLITE |

| 4 | Hydraulic oil motor | INTERMOT |

| 5 | Cylinder Air Valve | SMC |

| 6 | Air Cylinder | SMC/AIRTAC |

| 7 | PLC | OMRON |

| 8 | Rotation Plant Servo Motor | OMRON |

| 9 | Low-voltage electrical components | Schneider |

| 10 | Temperature controller | OMRON |

| 11 | Material used for mould | Mould Stainless Steel |

WIB-40 Automatic Injection Blow Molding Machine

WIB-40 Automatic Injection Blow Molding Machine WIB-40 Injection Blow Molding Machine

WIB-40 Injection Blow Molding Machine Automatic PE Bottle Blow Molding Machine

Automatic PE Bottle Blow Molding Machine PP Bottle Making Machine

PP Bottle Making Machine PP Bottle Blow Molding Machine

PP Bottle Blow Molding Machine Automatic PP Bottle Blow Molding Machine

Automatic PP Bottle Blow Molding Machine Medicine Bottle Making Machine

Medicine Bottle Making Machine Cosmetic Container Making Machine

Cosmetic Container Making Machine